YES. I find solutions for problems in textiles.

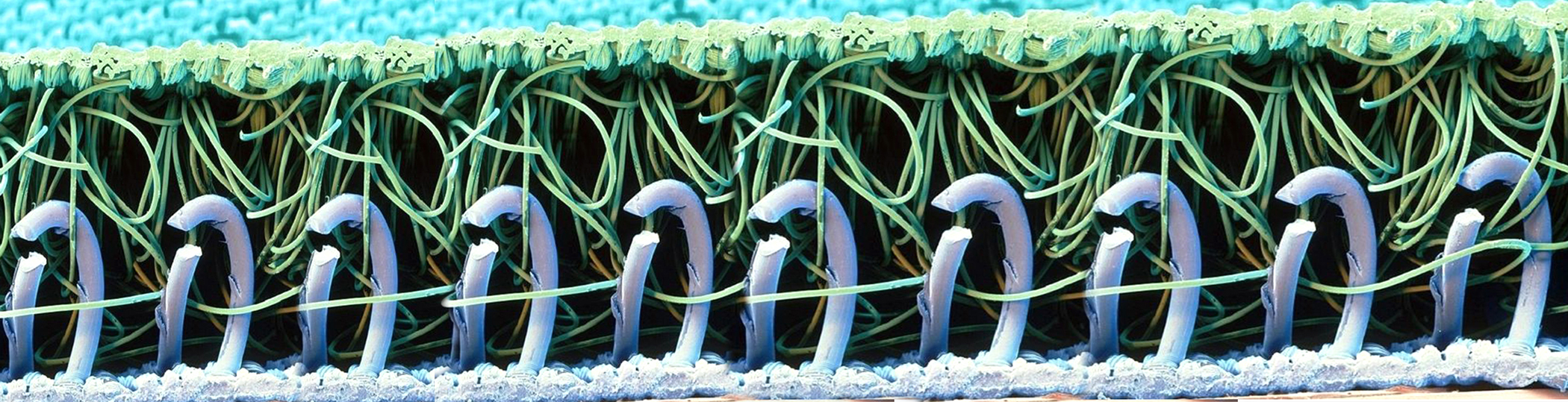

Failure analysis is just one part of my job at CHT Switzerland AG. But what do we actually mean by failure analysis? Every textile goes through a multitude of processes before it ends up in the garment: from fibre production for yarn and twine manufacturing to the formation of the textile surface (woven fabrics, knitted fabrics, non-wovens) to the diverse textile finishing processes including dyeing, property optimization and other effects. Chemical, physical and textile technical factors play an important role throughout the entire process. And so, of course, a variety of defects can occur along the entire production chain that reduce the quality of the fabric in question. Common defects in textiles can include stains, yellowing or holes, for example.

Root cause analysis for quality improvements

When it comes to failure analysis, a broad textile-related technical knowledge of the entire textile industry, in addition to textile material and fabric knowledge as well as a deep understanding of textiles testing, standardization systems and various practical application techniques are required. With the help of chemical analysis, physical tests, microscopic examinations and instrumental analysis, I and my team get to the bottom of what causes these defects. My contributions provide valuable assistance to our customers so that they can, in the best case scenario, eliminate the textile damage on site, leading to measurable improvements in fabric quality.

A mix of tasks provides maximal motivation

In addition to failure analysis, my other areas of responsibility include laboratory and analysis service in the fields of finishing, coating, pretreatment, PET flake recycling, analytics and microscopy. Our laboratory service often includes technical formulation and process recommendations accompanied by a wide variety of textiles testing, as well as the delivery of technical application recommendations directly to our customers or to our Area or Regional Sales Managers (ASM / RSM). In my role as team leader, I manage three laboratory technicians and one to three apprentices. Together we ensure that our work is carried out on time and with the correct content, including the preparation of laboratory reports in all the areas I mentioned previously. In addition, when I need to, I accompany our ASM / RSM together with other application technicians on customer field trials or collaborate with other teams to prepare technical documentation and sales aids. Another important pillar of my work is transferring knowledge to our apprentices as a practical trainer, to my colleagues on my team (e.g. through technical training), to our ASM / RSM (e.g. as a presentation at the technical conference), to training institutes (e.g. during practical visits from schools) or—in my secondary occupation as a specialist teacher of EFZ Textile laboratory technicians—to my own students. It’s really the variety of tasks and the diverse responsibilities I have that ultimately keep me so motivated as I do my day-to-day work for CHT.