YES. Partnerships with scientific organisations

The field of fibre auxiliaries encompasses indispensable process aids for the manufacturing and processing of yarns and fibres. The primary role of fibre auxiliaries for the respective process step involves adjusting the required fibre-to-metal friction and fibre-to-fibre friction and preventing electrostatic charges. Yet, the uses of fibre auxiliaries extend far beyond the process step in which they are deployed. As a rule, fibre auxiliaries also help to make it possible to satisfy the requirements of downstream processing steps, with examples including the production of nonwoven fabrics, carpets, and yarn spinning.

Maintaining relationships is an important part of what we do

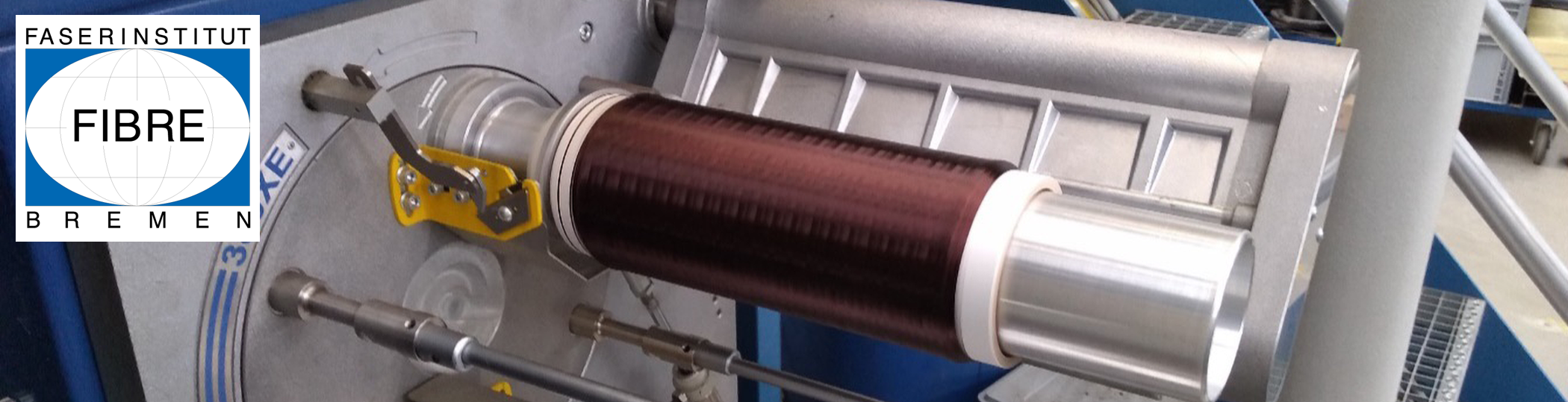

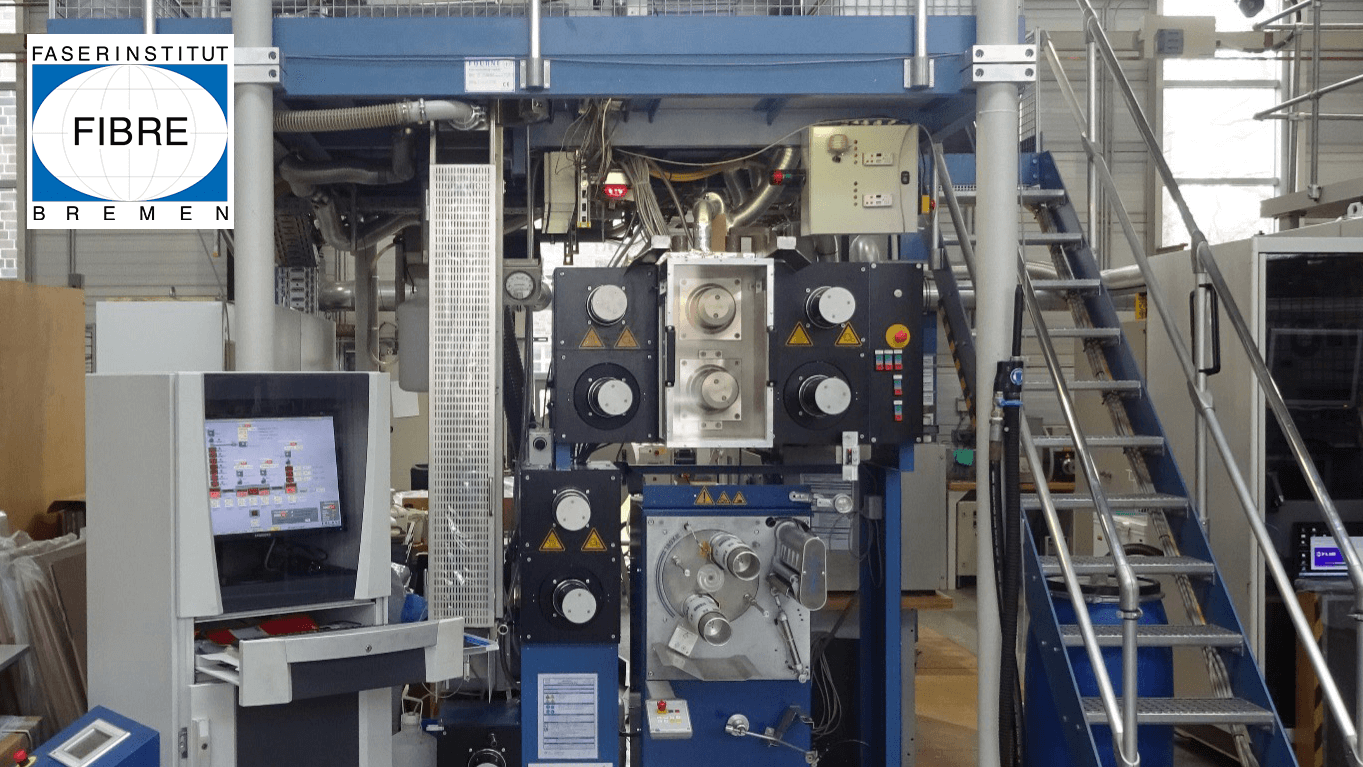

Still, there continues to be tremendous potential for development, highlighting the textile industry’s position as one of Germany’s most innovative industries. That is why maintaining relationships with key scientific institutes and organizsations like Faserinstitut Bremen, RWTH Aachen, STFI and DITF Denkendorf is so important to CHT and the fibre auxiliaries field of application, both as a sponsor of corresponding project-specific partnerships and in the form of training and further education. These institutes are taking part in innovative research projects, including ‘Stereocomplex PLA for technical fibre applications’ (Faserinstitut Bremen), ‘AlgaeTex: making it possible to use microalgae as a raw material basis for plastic filaments to produce sustainable textile products’ (RWTH Aachen), ‘Carbon fibre recycling’ (STFI) and ‘Textile-based drug delivery systems’ (DITF).

We safeguard the financial success of the field of application

We, as an application field fibre auxiliaries, are lending our support to the pursuit of these exciting new possibilities by selecting the most suitable process aids, thereby safeguarding the future financial success of the application field. From several fruitful discussions, we are proud of the esteem in which our technical expertise is held by our partners.