YES. Everyday work that never gets boring.

Processing laboratory inquiries is a daily task in the Application Field Garment, but it's always new and intellectually stimulating. Inquiries arise for a wide variety of reasons, for example from team conferences with our CHT colleagues from other CHT countries, in meetings with our developers or at the request of our customers. Most of the time it's a matter of product analyses, product comparisons, product development or review of competitor products. As soon as the request is transferred to me, the first thing I consider is what exactly the goal of the investigation in question is. Then I determine how we can carry out the testing and what we'll need in order to do that within the deadline. All the important facts about the inquiry are recorded in our digital system, which our entire team can access.

Coordinating workflows for the best possible results

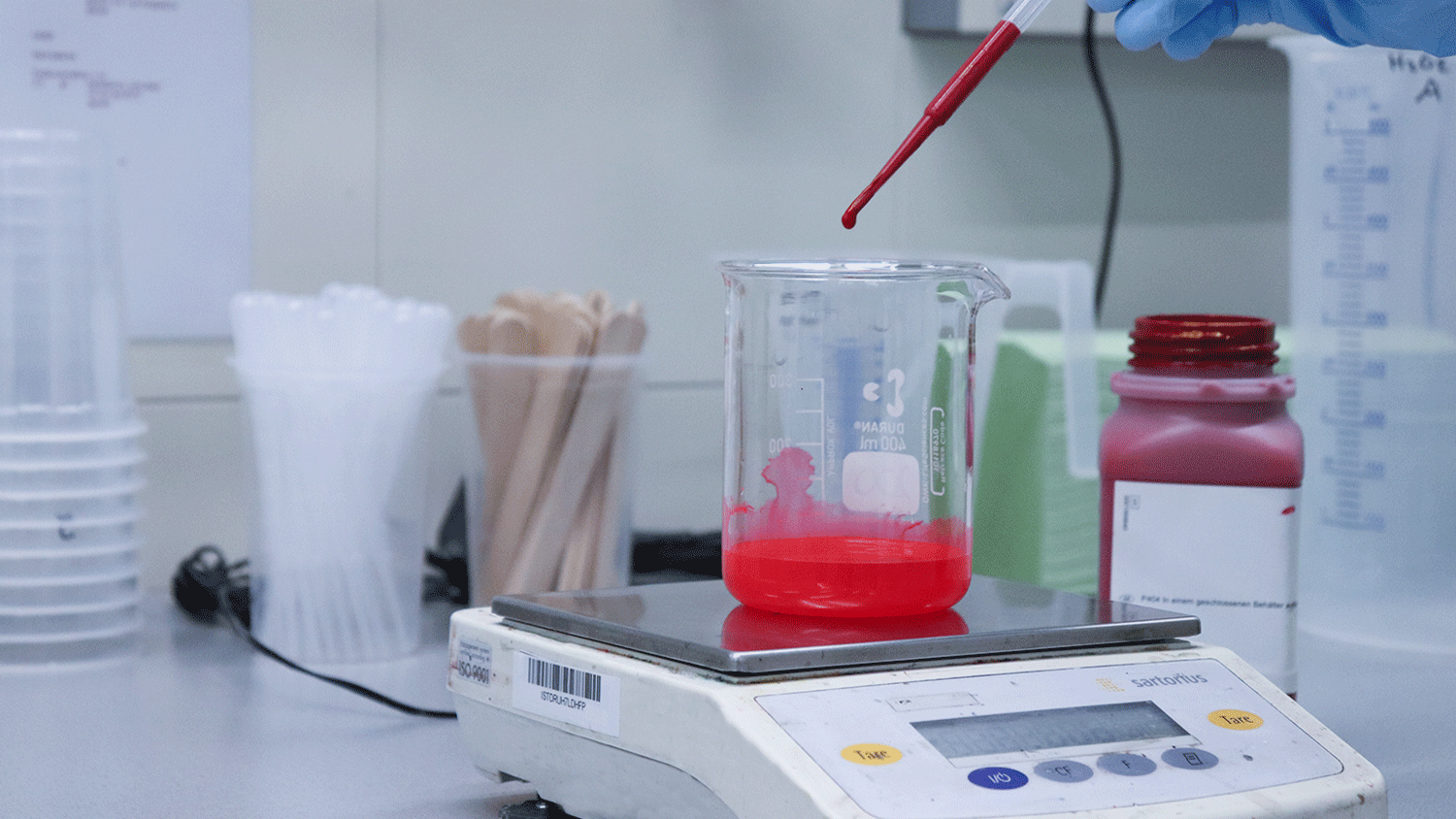

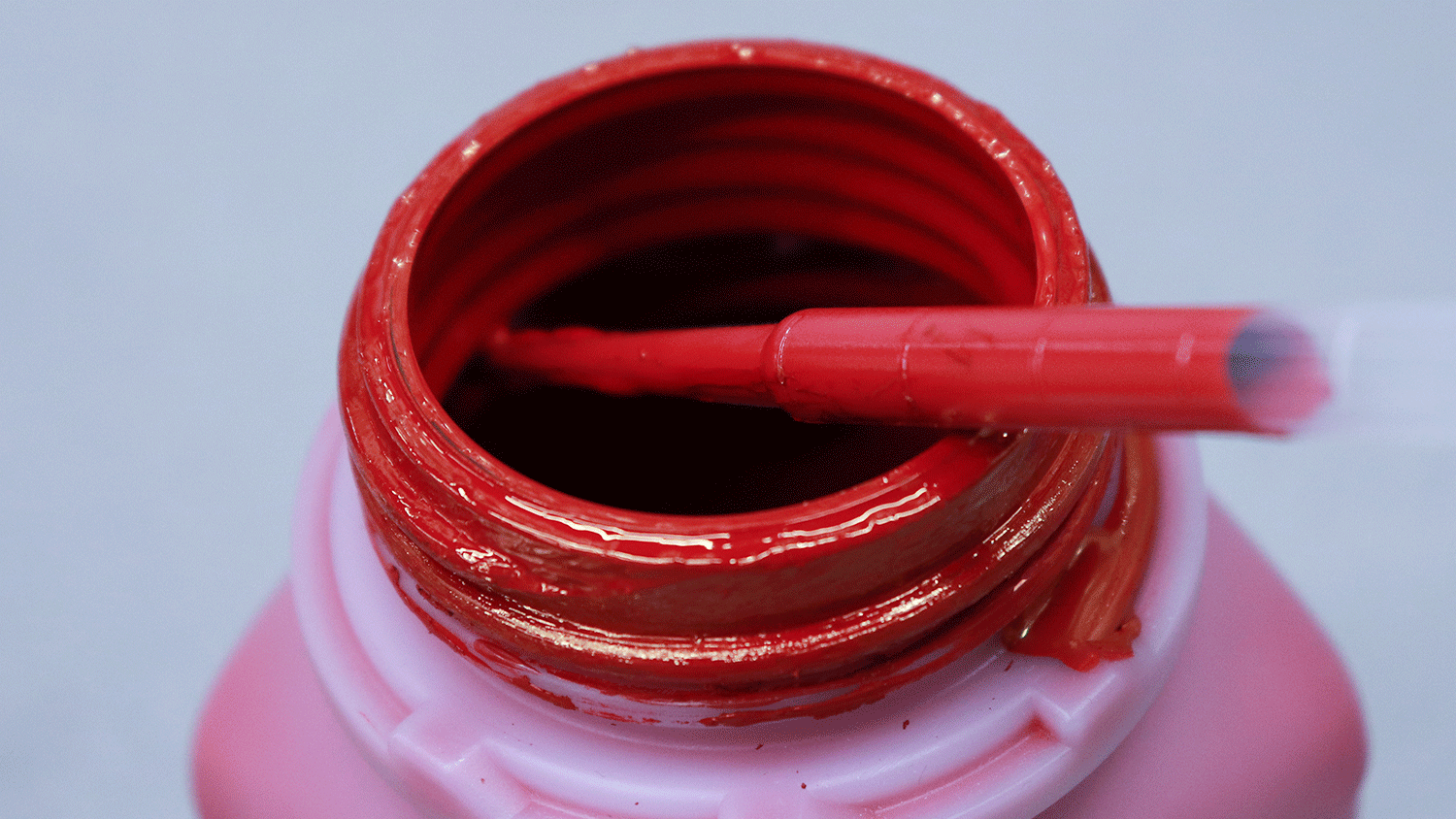

After entering all the data related to the inquiry, I go through all of the details with the lab technician who will be performing the practical tests here in the lab. Precise coordination is important here so I can ensure nothing is forgotten or overlooked. Once we've completed the task in theory, the practical experiments in the lab begin. Throughout the process there are consultations on how the experiments are going, whether there are any anomalies or unexpected results. We document all of that on our digital platform. Depending on the results, it may also be necessary to change the parameters we've defined or conduct additional testing.

Knowledge that grows with every inquiry

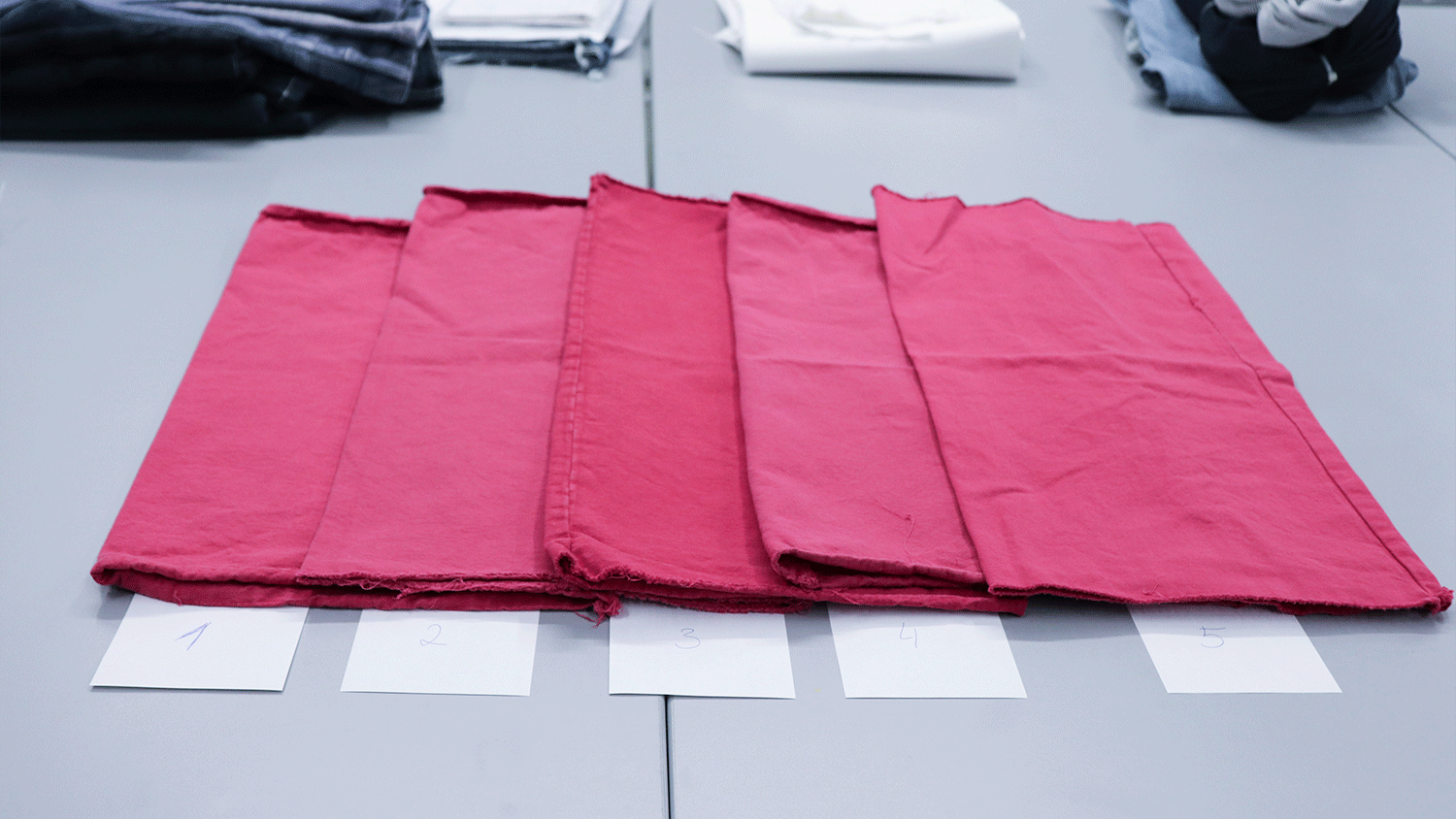

Once we've wrapped up all of the testing, we summarize our findings and conclusions, inform our customers or other stakeholders as necessary, then we close out the inquiry. The textile samples are filed in the lab and stored for a period of time so we can refer to them again if necessary. Processing a laboratory inquiry is exciting every single time. You always gain new insights into processes, enrich your knowledge of our own products or competitor products, and you really stay close to the laboratory the entire time, which means you always stay connected to your practice.